In the world of modern manufacturing, materials play a crucial role in determining efficiency, durability, and overall productivity. One material that has gained significant attention in recent years is tungsten carbide metal. Known for its exceptional hardness and resistance to wear, tungsten carbide metal is transforming how industries approach manufacturing, cutting tools, and machine components. Its unique properties are making production processes faster, more precise, and cost-effective, ultimately shaping the future of industrial development.

The Unique Properties of Tungsten Carbide Metal

Tungsten carbide metal is a compound composed of tungsten and carbon. Its most notable property is extreme hardness, which makes it almost as hard as diamond. This hardness allows tools made from tungsten carbide metal to cut through tough materials with minimal wear over time. In addition, tungsten carbide metal has high resistance to heat and corrosion. This combination of durability and resilience makes it an ideal choice for industries that rely on precision and efficiency. Manufacturing processes benefit greatly because machines and tools made from this material last longer and maintain accuracy even under heavy use.

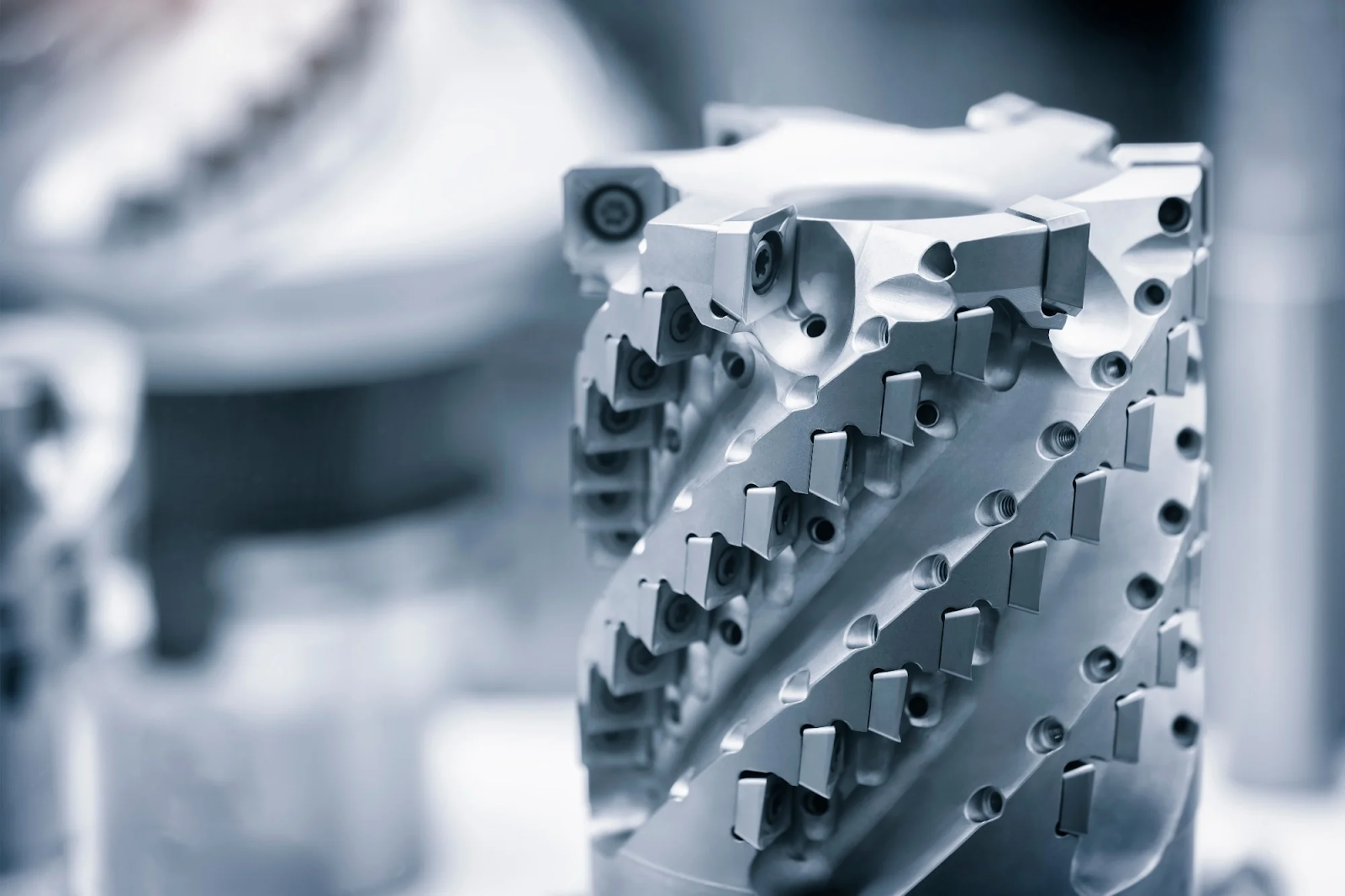

Applications in Cutting and Drilling Tools

One of the most common uses of tungsten carbide metal is in cutting and drilling tools. Industries such as automotive, aerospace, and construction rely heavily on tools that can maintain sharpness and withstand high-speed operations. Tungsten carbide metal allows saw blades, drill bits, and milling cutters to cut through metals, plastics, and even composite materials efficiently. This not only improves productivity but also reduces downtime for tool replacement. The precision offered by tungsten carbide metal tools ensures consistent quality in manufactured parts, which is critical for modern industrial standards.

Enhancing Machining Efficiency

In machining processes, time and accuracy are key factors. Tungsten carbide metal helps manufacturers achieve both by providing tools that require less frequent sharpening and replacement. Because of its toughness, tungsten carbide metal reduces the friction between the tool and the material being cut, which results in smoother operations and less heat generation. This efficiency allows factories to produce more units in less time without compromising on quality. The ability to maintain consistent performance over prolonged periods also reduces manufacturing costs, making production more sustainable and economically viable.

Role in Wear-Resistant Components

Beyond tools, tungsten carbide metal is increasingly used in wear-resistant components. Parts such as bearings, valves, and nozzles are often exposed to friction, high temperatures, and corrosive environments. Incorporating tungsten carbide metal into these components significantly extends their lifespan. For manufacturers, this means fewer interruptions due to equipment failure and lower maintenance costs. The long-lasting nature of tungsten carbide metal components ensures that machinery operates reliably, which is essential for industries that run around the clock.

Supporting Innovation in High-Precision Industries

High-precision industries, including medical device manufacturing and electronics, are also benefiting from tungsten carbide metal. Its ability to maintain sharp edges and resist wear allows for the production of tiny, intricate components with exact specifications. This precision is particularly important in fields where even minor deviations can impact performance and safety. Tungsten carbide metal is therefore not only supporting current manufacturing needs but also enabling innovations that push the boundaries of technology.

Conclusion

Tungsten carbide metal is proving to be a game-changer in modern manufacturing processes. Its exceptional hardness, heat resistance, and durability make it an essential material for cutting tools, wear-resistant components, and high-precision applications. By increasing efficiency, reducing downtime, and supporting innovation, tungsten carbide metal is shaping the way industries approach production. As technology continues to evolve, the role of tungsten carbide metal in manufacturing is likely to grow even further, ensuring that industries can meet the demands of a fast-paced and highly competitive world.

Leave a Reply